GOLD

Gold is a chemical element with symbol Au (from Latin: aurum) and atomic number 79. In its purest form, it is a bright, slightly reddish yellow, dense, soft, malleable and ductile metal. It occurs often in free elemental (native) form, as nuggets or grains, in rocks, in veins and in alluvial deposits. It can occur in a solid solution series with the native element silver and also naturally alloyed with copper and palladium. Less commonly, it occurs in minerals as gold compounds.

This metal has been a valuable and highly sought-after precious metal for coinage, jewelry, and other arts since long before the beginning of recorded history. Gold’s economic and cultural significance as a sign of status, a store of value and a mechanism of exchange, remains, while new diverse uses for gold, as the basis of investment products and cutting-edge technology, have emerged including gold Exchange Traded Funds as well as uses in dentistry, the space industry and fuel cells.

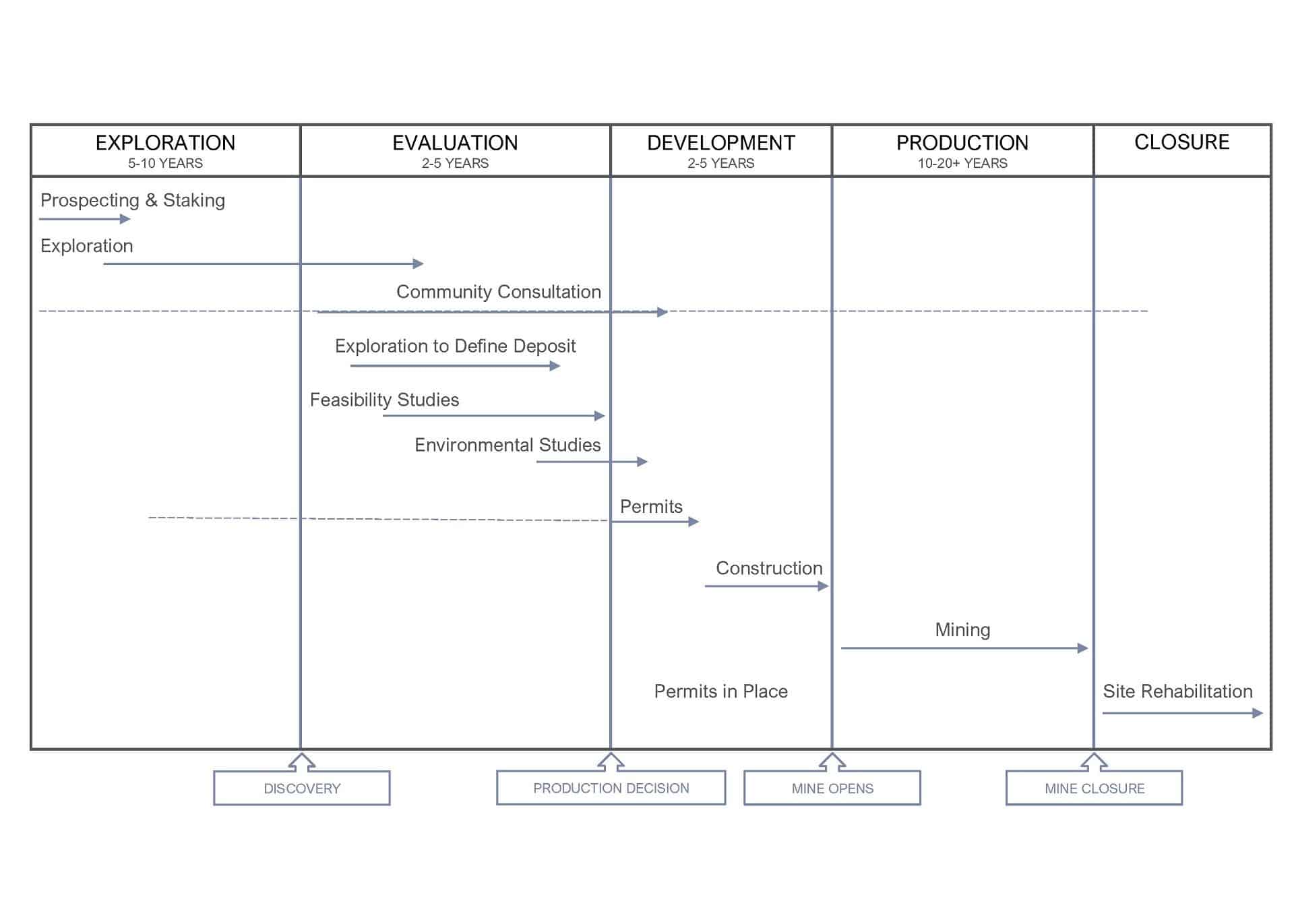

MINING CYCLE

Although the addition of even one mine can bring substantial benefits to society the wins do not come quickly or easily. It takes a great deal of will, effort and time to discover a viable ore deposit and bring it into production.

There is no way of predicting where profitable ore deposits will be found. Each prospector, explorationist and investor may fervently hope for the next “big find” but only about one mineral exploration project in ten is taken to the drill stage, and one drill program in 1000 finds a viable mineral deposit; hence, less than one project in 10,000 becomes a mine. It typically takes ten to fifteen years of exploration, data analysis, planning and financing to bring a mine into production.

The Life of a Mine (Example)

Prospecting & Claim Staking (1-2 years)

The mining process starts with prospecting and claim staking. Explorationists hike through the bush to stake claims, collect rock and soil samples and comb the land for signs of an ore body. Because it is impossible to predict where a viable ore deposit will be found, explorationists require access to as large an area of land as possible. Ultimately, only a small number of claims will show enough promise for diamond drilling, or advanced exploration.

Basic & Intermediate Exploration (3-4 years)

If there are favourable signs of above normal mineral levels, basic and intermediate exploration will begin. Exploration activities include geological mapping and aerial surveys to obtain detailed geological data. Geophysical and geochemical tests on the ground detect the possible presence of valuable minerals through measurements of electrical conductivity, magnetic fields, or sampling of rock, soil or water. Explorationists may explore rock formations by extracting core samples with a diamond drill, stripping (removing soil and vegetation) or trenching (removal of rock using jack hammers and explosives).

Advanced Exploration (5-10 years)

Advanced exploration marks the start of bulk sampling and drilling from underground tunnels. Roads are built, field camps increase in size and heavy equipment is brought in. At this stage, explorationists and mine planners gather all available data to predict the profitability of a mine and the best methods of extracting the ore.

Development & Production (20 years)

Mining – the accessing/removal of minerals from the earth – is a complicated operation requiring methods tailored to each ore deposit. Open pit mining is used to mine ore deposits close to the surface. Huge shovels and trucks deliver a steady supply of ore to the mill. Underground mining requires more intricate methods to access/remove ore. The underground mine is a complex operation transporting workers, equipment, supplies and ore; pumping groundwater; and supplying power, water and fresh air.

Ore from the mine is transported to a mill for crushing and grinding. Once the ore is reduced to a sand-like fineness, minerals are separated with the use of chemicals (flotation), gravity, magnetism and electrical conductivity. Flotation, the most common method, involves adding water and “air-seeking” chemicals to the ore. The chemicals adhere to the minerals and rise like bubbles to the surface. The froth is skimmed, dried, filtered and shipped as mineral concentrate.

After separation, metals are recovered from minerals by smelting, acid leaching and even bacterial activity. The refining process then produces purified metal products tailored to client needs.

Separation and recovery extract many different minerals and metals from the same rock. The remaining ground rock (tailings) is pumped to tailings ponds. Gases and water used in production are treated and then released or reused. Milling, separation, smelting and refining are controlled by specific conditions set out in a mine’s permits and Environmental Compliance Approvals. Mines must monitor their impact on air and water quality and prepare public reports summarizing effluent and emissions data.

Closure & Rehabilitation (2-10 years)

Even before a mine opens for production, plans are in place for the future reclamation of the land. Every advanced exploration and mining project includes a closure plan to restore lands to a natural state upon completion of exploration and mining activities. After various stages of production, buildings are razed, trees and natural grasses planted and wildlife habitats restored. This temporary land use is one of mining’s unique attributes. While new manufacturing plants, highway expansions, housing developments or office towers may permanently take over tracts of greenbelt, farmland or forest, mines are rarely permanent facilities.